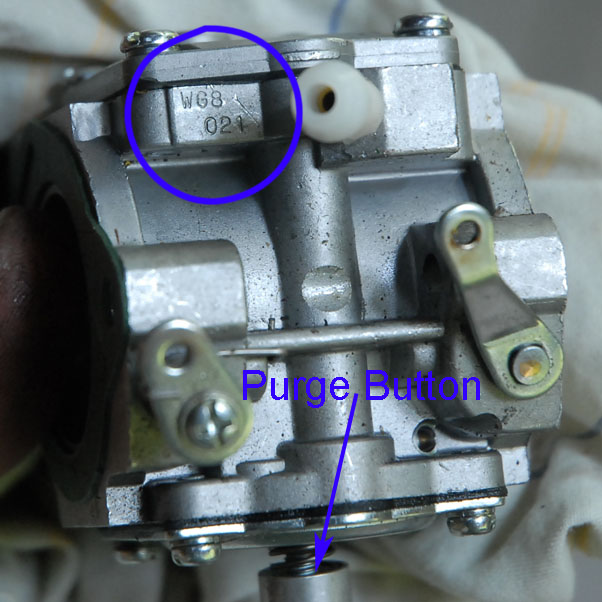

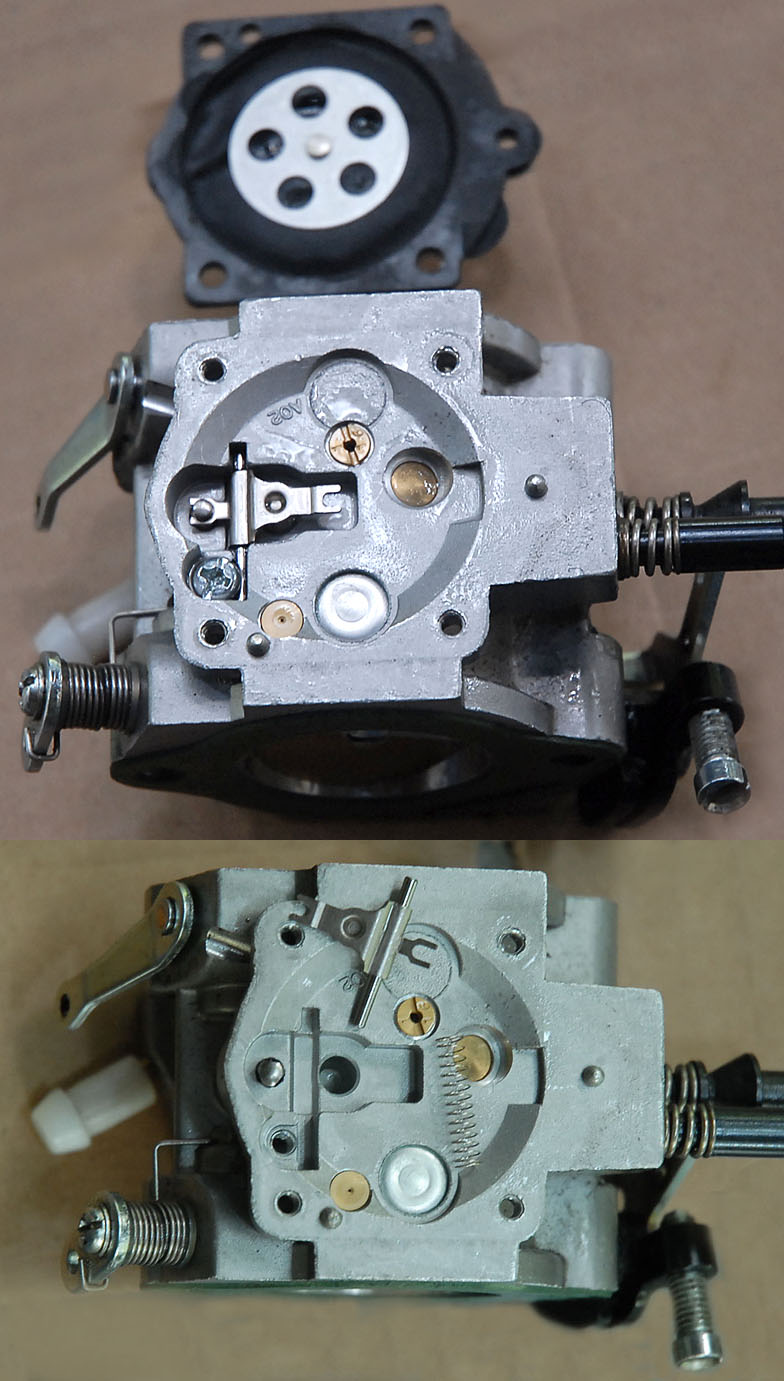

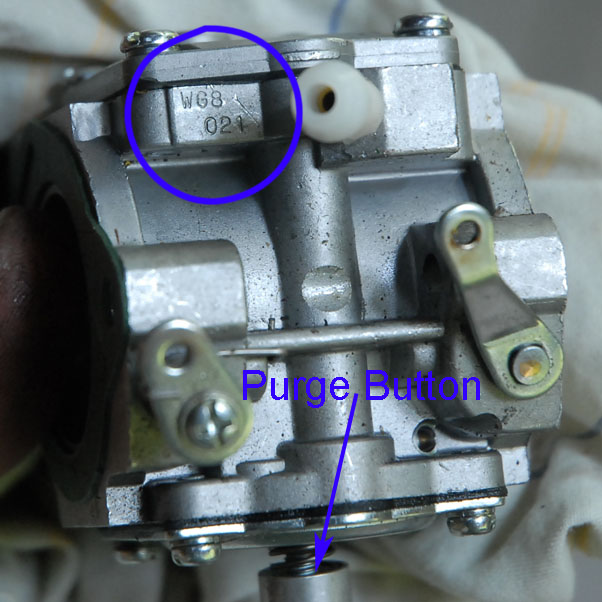

This shows the disassembly of Walbro WG-8 carb that was

supplied

with the Radne Aero 120 on a Mosquito NRG. Note the purge

button

on the diaphram cover - this has apparently been discontinued on later

models, but is very useful for bleeding air from the fuel lines.

Apparently some units are now shipping with the WG-10 carb.

A comparison of part numbers on Walbro's website shows that they are nearly identical. The only differences I could find were:

- The WG8 lists a Nozzle Jet part 112-3051, the WG10 has this blank

- Metering cover screws(4) - The WG8 uses 96-589 and the WG10 uses 96-603

So presumably the information on this page will apply to the WG-10 in most respects. There is also a WG-12, which uses the

same repair kit, which implies a great deal of similarily for that model as well.

This exploded parts diagram is for the WG-8, but applies to the WG-10 (with slight exceptions noted above).

Thanks to Greg Dewenter for the edited form of the parts diagram below (which is better than the one

currently on Walbro's parts page):

Parts are available on

Walbro's Website

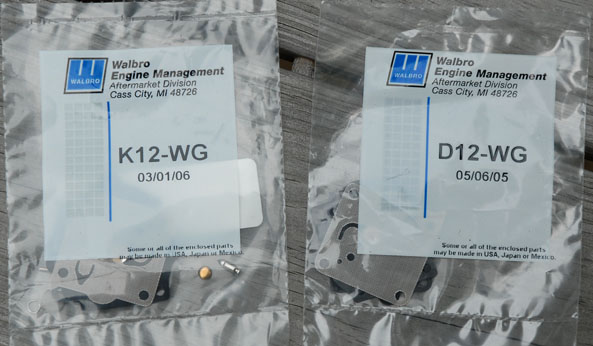

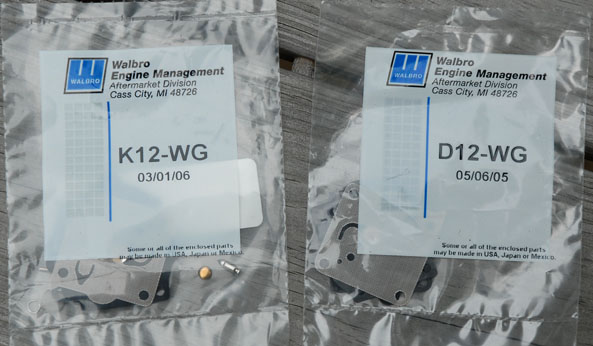

There are two repair kits available. The K12-WG has almost

all

the parts, including needle, fuel strainer screens, etc. Note

that it does

not

have

a metering spring. The D12-WG has just the gaskets and

diaphragms

(metering and pump).

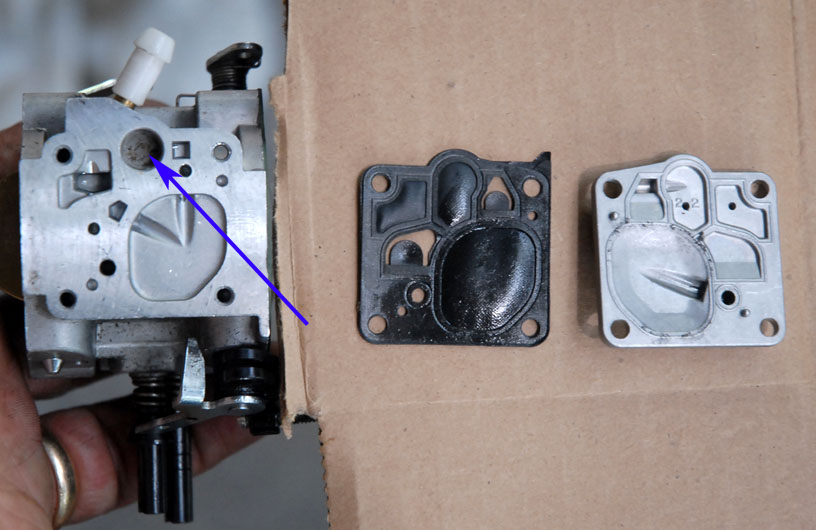

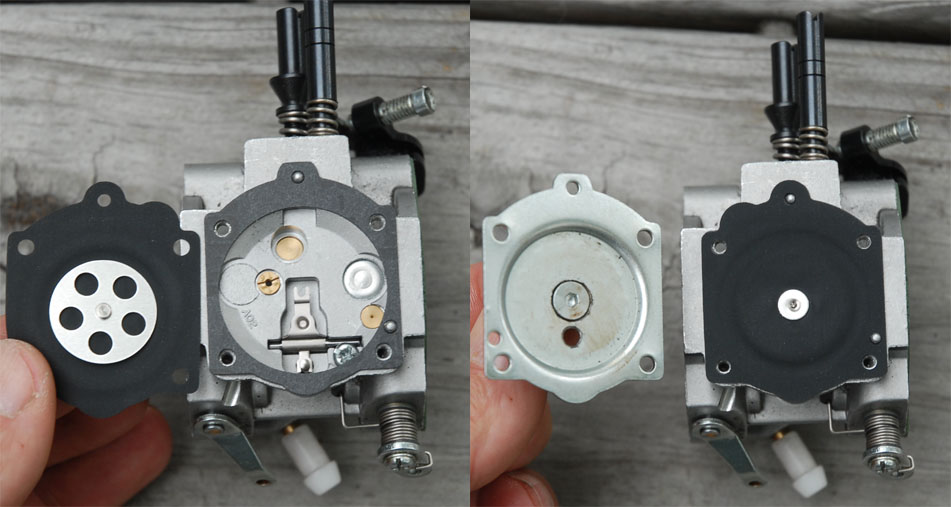

The figures below show the operation of the fuel pump and the fuel pump

diaphram on the WG-8. Air impulse pressure on one side of the diaphram

serves to pump the fuel on the other side. The blue arrow

points

to the final fuel filter screen (which has collected some debris in the

photo). The operation diagrams and explanations on this page

are

excerpted from theWalbro Service Manual:

http://wind-drifter.com/technical/WalbroServiceManual.pdf

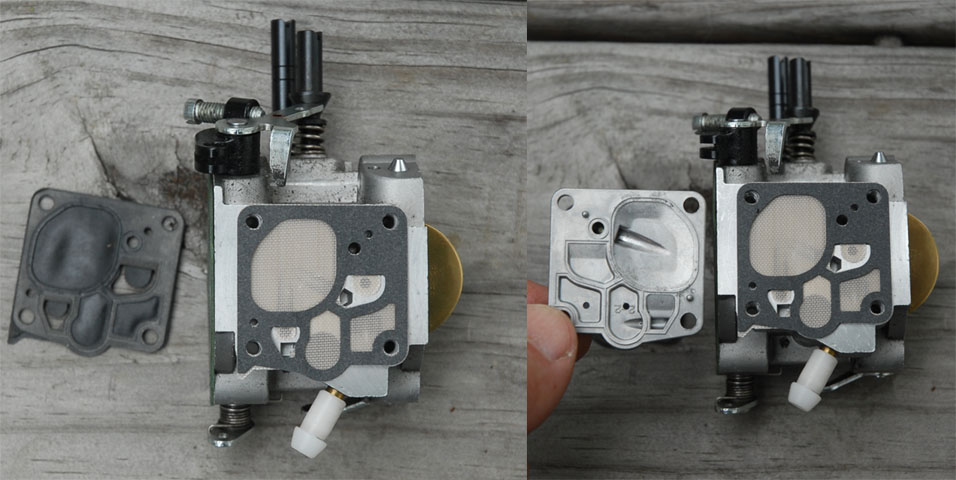

The figures below describe the fuel

metering system and show 2 stages of dis-assembly:

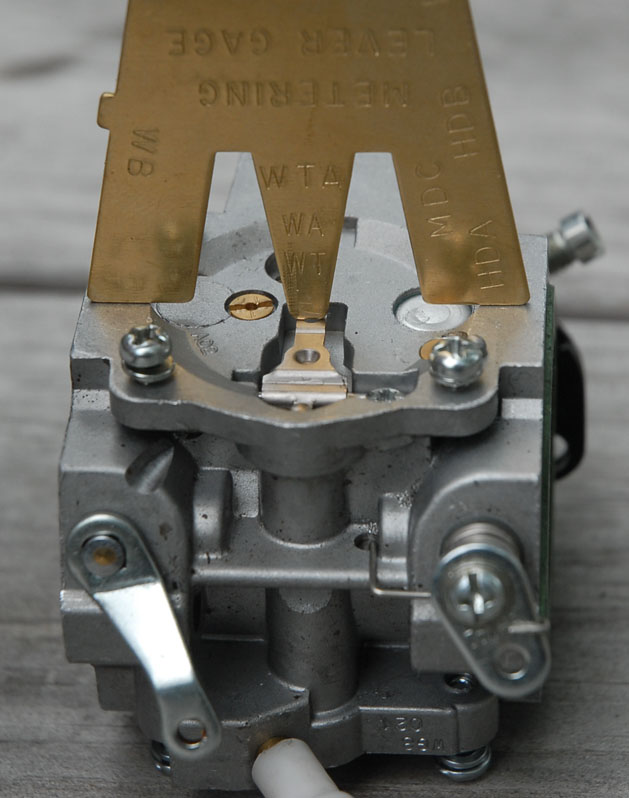

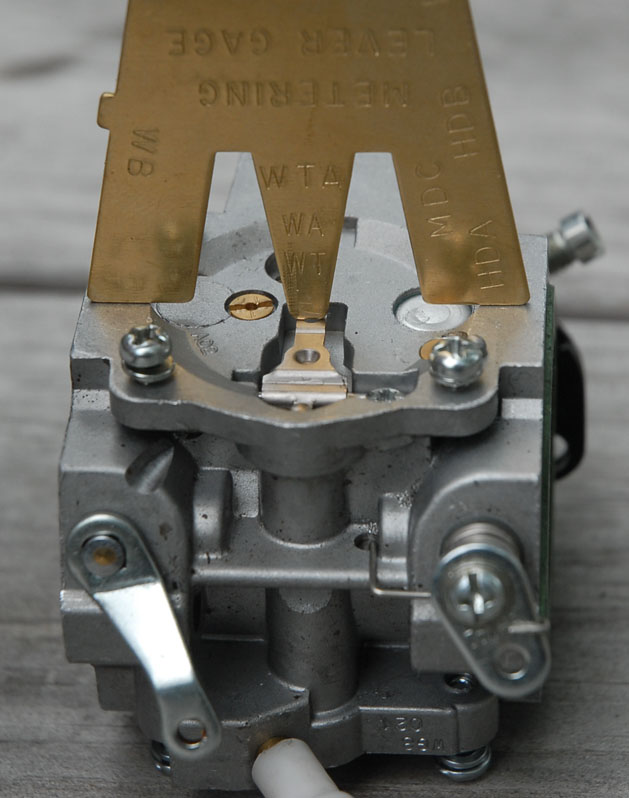

Walbro has a gage for setting metering lever height, as shown below.

You can buy the gage from Walbro, or you can make your own.

If

you download

WalbroGage.pdf

you

can print out an exact scale image of the gage (be sure to turn off

page scaling when you print it). If it does not print

correctly,

there is a ruler in the picture you can use to scale it. The

dimensions are also included.

NEW

INFO - see discussion below on different diaphragms.

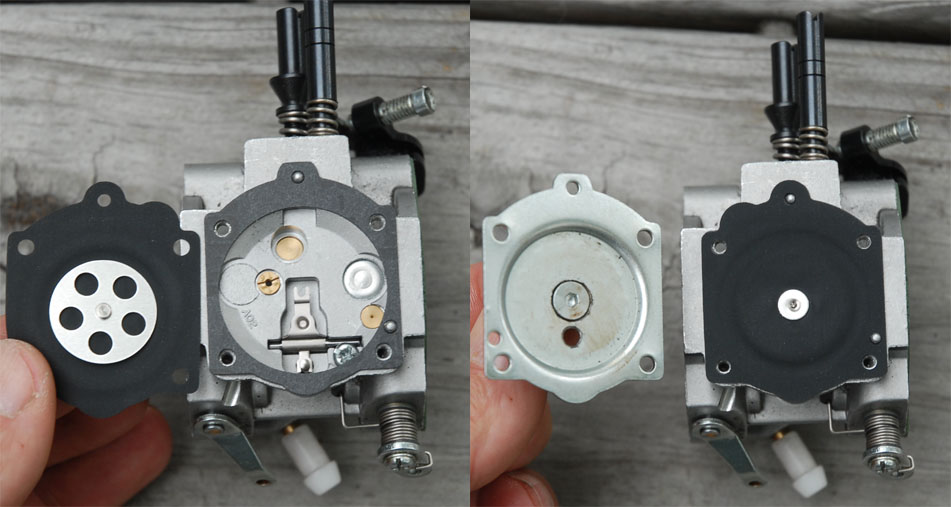

The figure below shows the installation of the metering

diaphragm and

cover.

Note

that on

this side the gasket goes on first, then the diaphragm.

(this is the opposite of the pump side). This is the newer

style

diaphragm, which does not have the interlocking tang for the metering

lever.

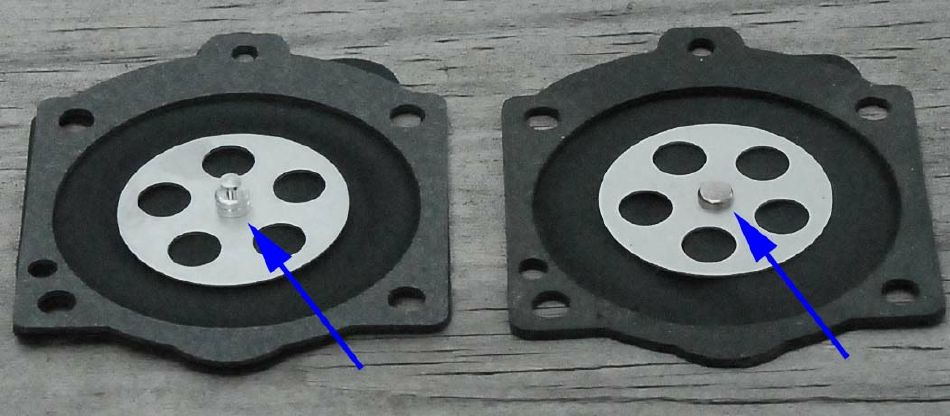

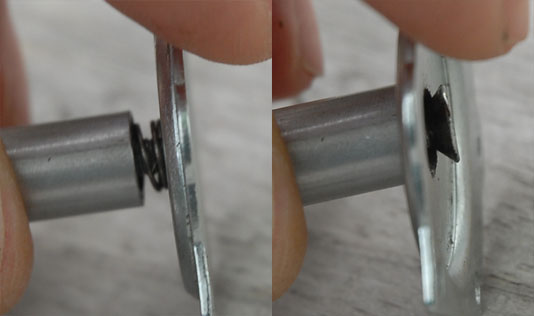

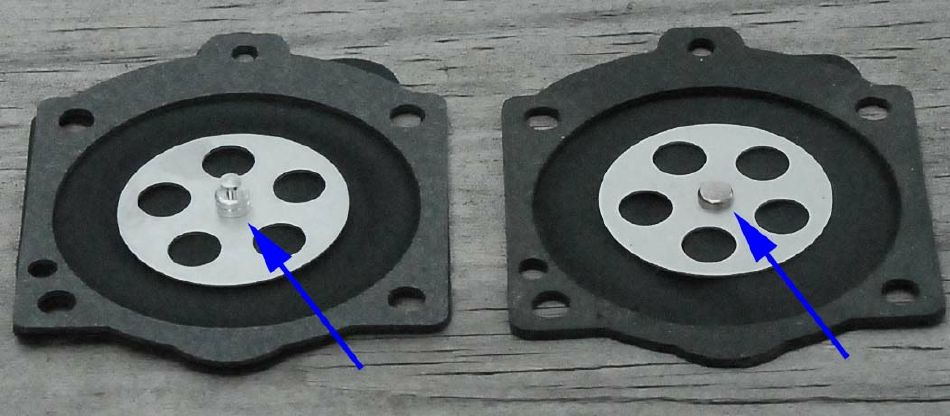

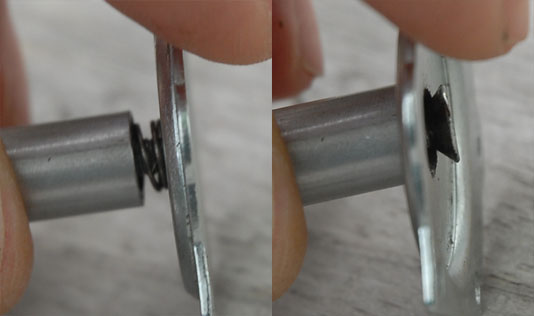

The following image shows the difference in the two diaphragm

styles

If you have the style with the interlocking tang, be sure it is

properly

engaged in the metering lever slot. When I bought the K12-WG

repair kit from a Walbro distributor, it did not have the tang (on the

right in the above image). The replacement kit I ordered from

Radne (part #32155) had the diaphragm on the left (in a bag dated Mar

'05 - so perhaps it was old stock)

Important: The

two diaphragms have different button heights, which will affect the

setting of the metering lever. The height I measured is

nearly 1

mm (0.94 mm is what I measured being as precise as I could). The button height on the interlocking button (not counting the

interlocking tang) is about 2 mm, while on the plain button it is only about 1 mm.

The

question is, which diaphram is the gage designed for? I

think

perhaps the button version (on the left), but that is

only a guess.

Responses from Walbro (US and Australia) were less than

totally

enlightening. Yes, there is a difference, yes, it should be

compensated for, no, it's not that critical, they are trying to

standardize settings, and so on. If you have information to

clear

this up, please contact me. But be aware that this is

currently

unresolved. Having said that, this is my current

Best Guess at the

correct settings:

- Diaphragm with tang

- set using the Walbro Gage WG tang (1.7 mm below the body surface). This is approximately flush to the

carb body surface

- Diaphragm

without tang - my logic says the lever should be ~0.95mm higher to

operate the same, therefore the lever should be set ~0.75mm below the

body surface.

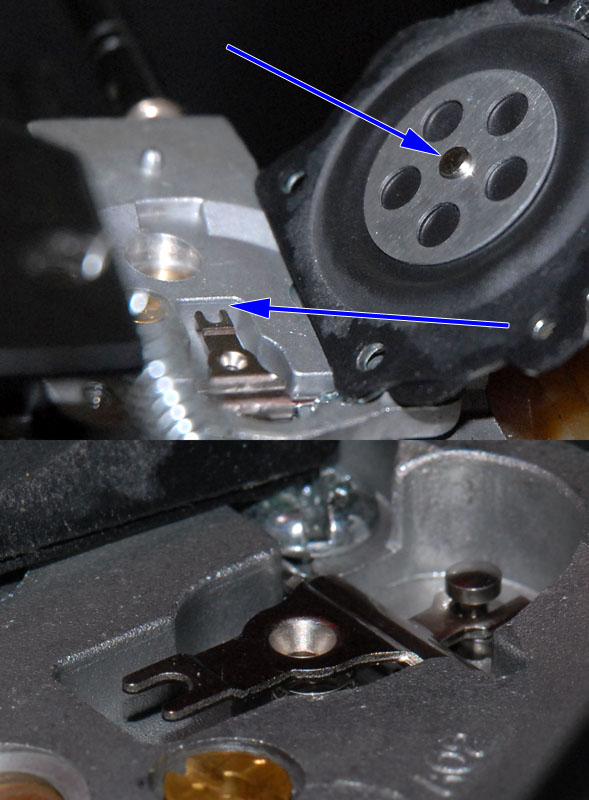

- The displacement of the metering valve is limited by the metal plate on the diaphram. When this contacts the carb body, no

further movement is possible. The WB gage sets the tang approximately even with the carb body. That means there is about 2mm

of movement possible with the interlocking tang. With the 1 mm high plain tang, only 1 mm of movement is possible. Maybe

that is enough, but erring on a low setting for the lever certainly risks fuel starvation.

This image further clarifies the travel limiting effect of the metal plate on the carb body:

If you find information which

is more authoritative than this, use it instead.

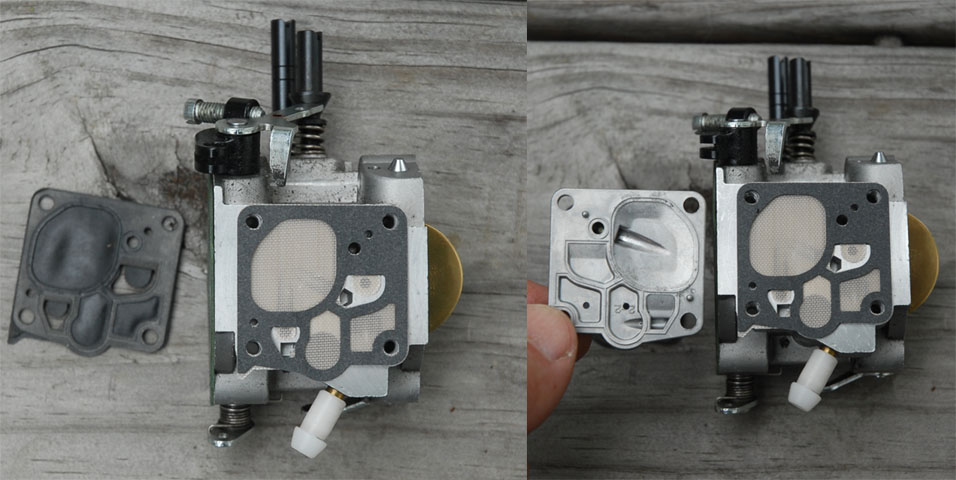

On the pump side the installation order between diaphragm and

gasket is

reversed - that is,

the pump

diaphgram portion goes

on first, then the gasket. Note that the

material for the

pump diaphragm has changed. The original (black) one is at

the

left, the newer version is translucent with an embedded mesh visible.

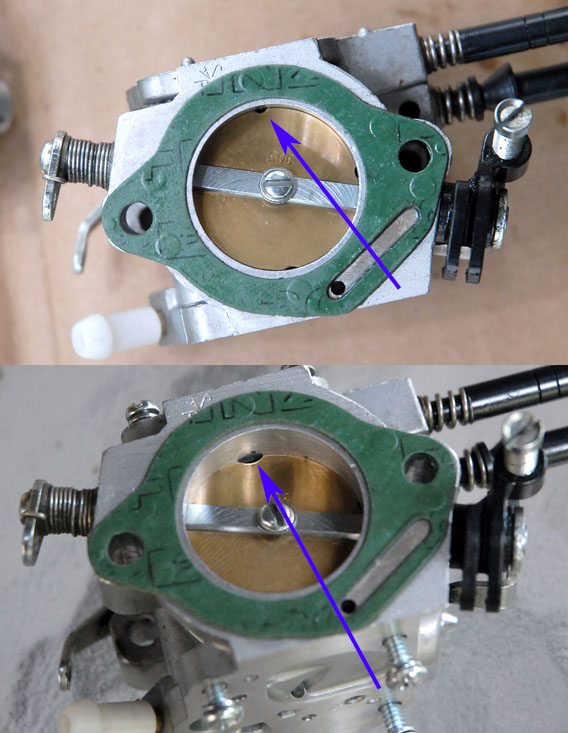

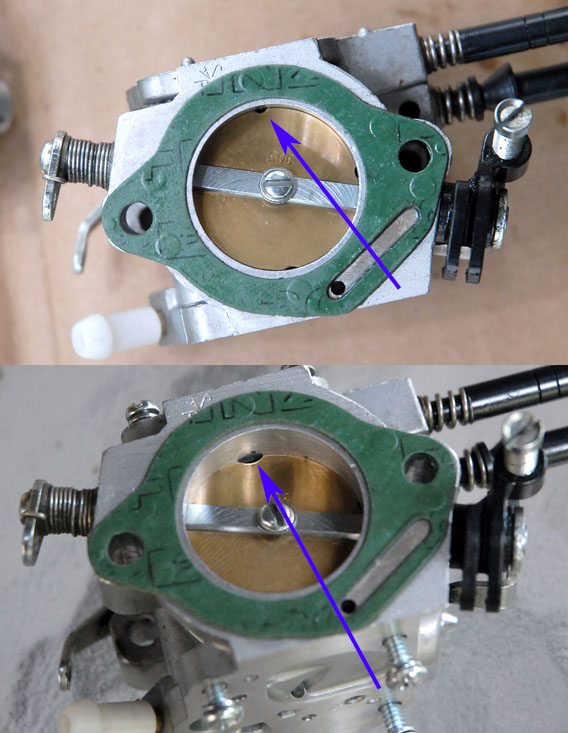

The figure below shows the throttle plate modification to improve idle

and mid-range operation. This is discussed in detail by Gerry

Farell:

http://webspace.webring.com/people/bf/flphg/idle_adaptation.html

The blue arrows show the notch before and after enlarging.

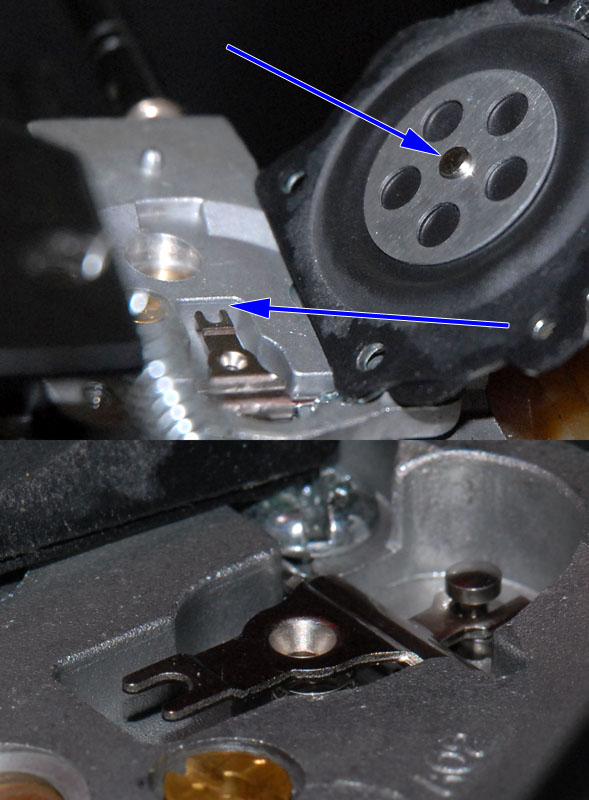

The newer carbs have done away with the purge

valve (see the figure

at the top of this page). I have found it very useful for

bleeding the fuel line, and I'm glad to have it. I understand

the

newer ones just have a hole in the metering diaphragm cover.

It

probably wouldn't be too hard to modify a cover to add a purge

valve. The pics below show how the original works.

It needs

to be able to press on the metering diaphragm/lever, without damaging

it.

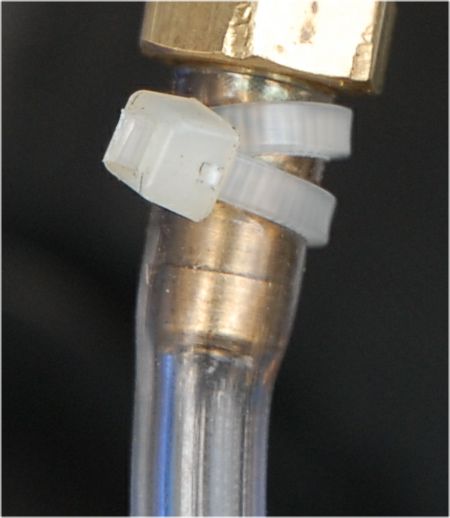

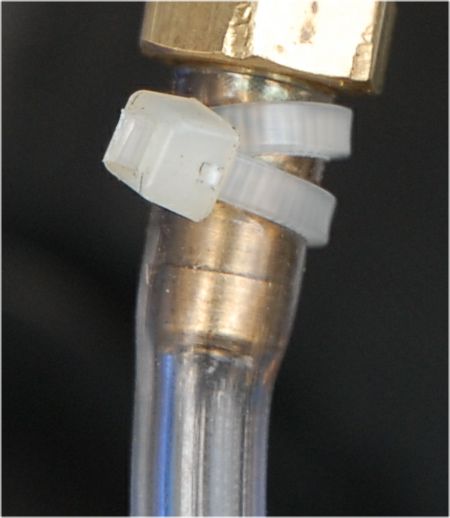

The

fuel line on many units has a 1/4" line, which can allow bubbles to

collect, especially in hot weather (fuel percolating). Even at

full throttle the fuel flow is not sufficient to move the bubbles from

a high spot in the line, where they eventually collect and slow fuel

flow enough to cause performance to decrease. A solution with

which many have reported success is to use a smaller 1/8" (~3mm) line,

which also involves removing the white plastic barb on the carb fuel

inlet. Before (top) and after(bottom) are shown below:

(The

silver braid is/was a failed attempt to suppress radio noise from the

ignition - resistor spark plugs are a much better solution).

I have discovered that the nylon

TyWraps work well for securing the fuel line, however, be sure to take

two wraps around the hose, as a single wrap will not apply uniform pressure all the way around.