This shows the disassembly of the electric starter that is supplied

with the Radne Aero 120.

This starter is manufactured in Italy by

Fiem. It is listed

in their

PDF Catalog.

(If that link is not working, there is a

cached copy here.

The Swedish Aerosports NRG (and probably any e-start Radne) uses the

3MG16552 Model Number starter.

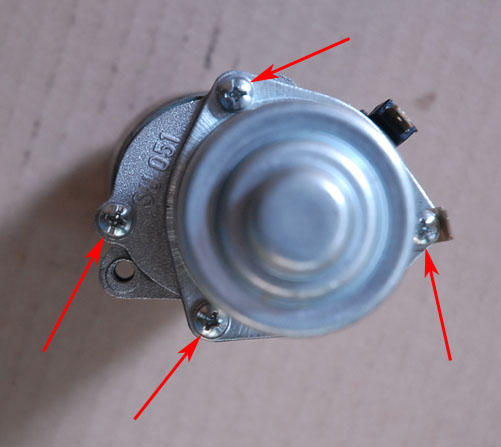

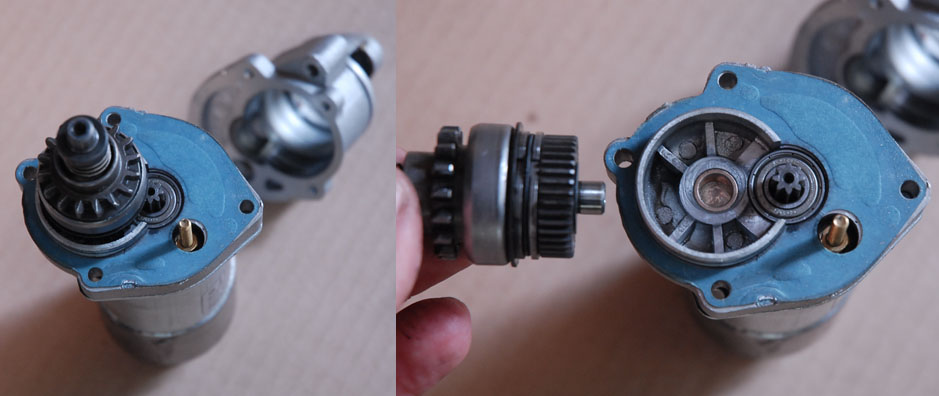

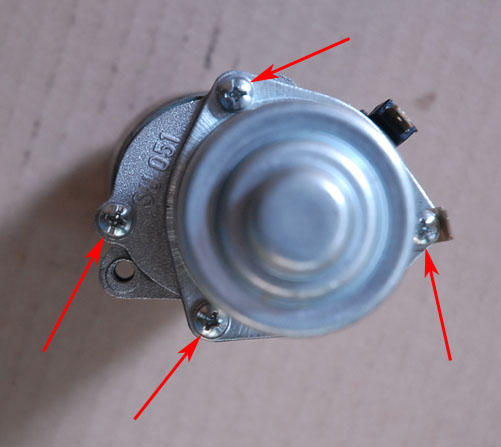

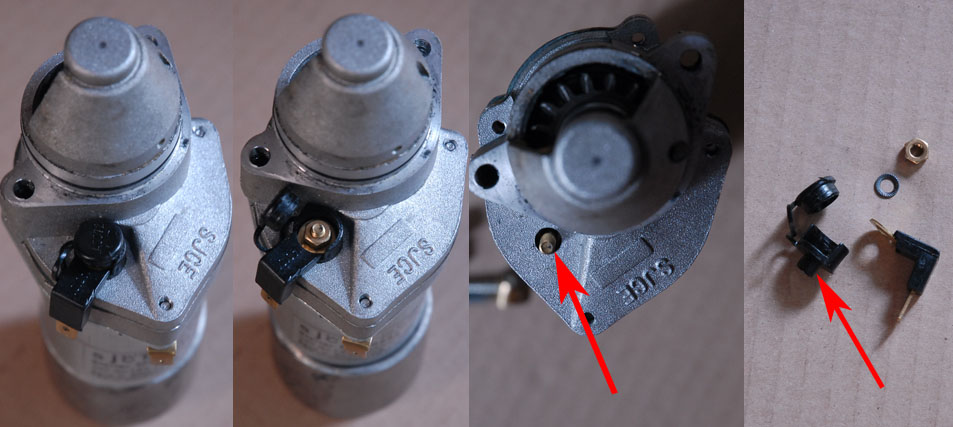

There are a total of four screws and one nut that must be removed to

disassemble the unit. This shows the 4 screws:

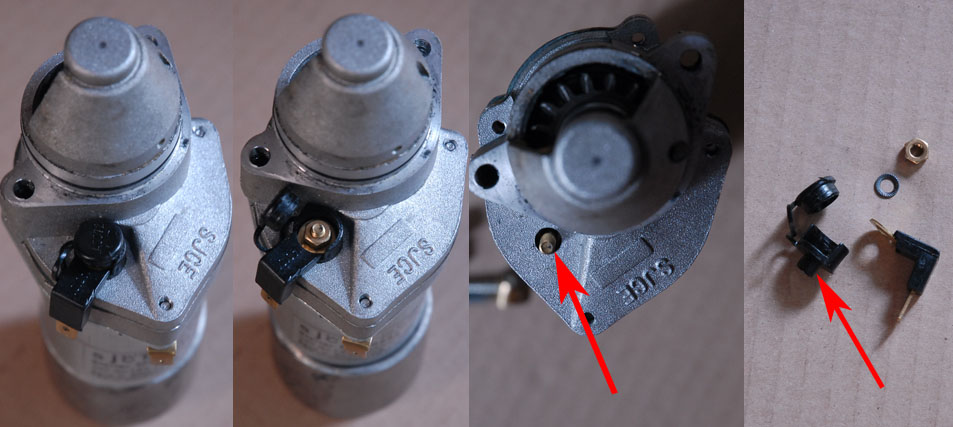

The nut that must be removed is part of the postive electrical

terminal. Pop up the protective cap that covers the terminal nut,

which will allow access to remove the nut and then the

terminal/insulator components. Note the skirt (indicated by the

red arrow in the 4th pane). This fits between the terminal stud

(red arrow in 3rd pane) and the housing, and has the important purpose

of insulating the positive terminal from the negative (ground)

terminal. Be sure this is properly reinstalled on reassembly, to

prevent a short circuit.

NOTE: I received the following helpful comment/update from Peter Mack of

Airtime Products:

On the flange of the pressed stator housing you'll find a centre punch mark near one of the holes. The motor must be re-assembled with this punch mark in the same location as it was originally or the poles will not be in the correct relation to the brushes and the motor does not spin. At least that's what I find.

You might also mention that the cap for the positive terminal insulator is glued in place these days and takes a concerted effort to get out.

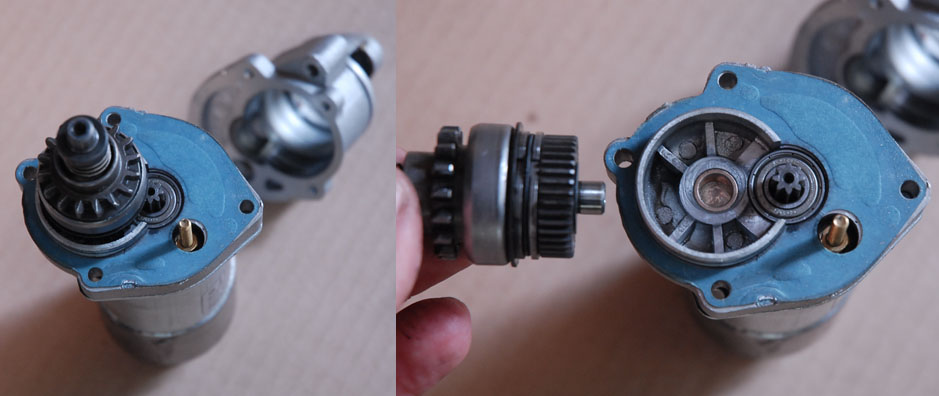

With the 4 screws and terminal nut removed, the nose casting may be

removed. The Bendix gear assembly may then be lifted from the

starter motor. If you later find two washers (that may fall off

during the dissaembly), they fit on both ends of the Bendix gear.

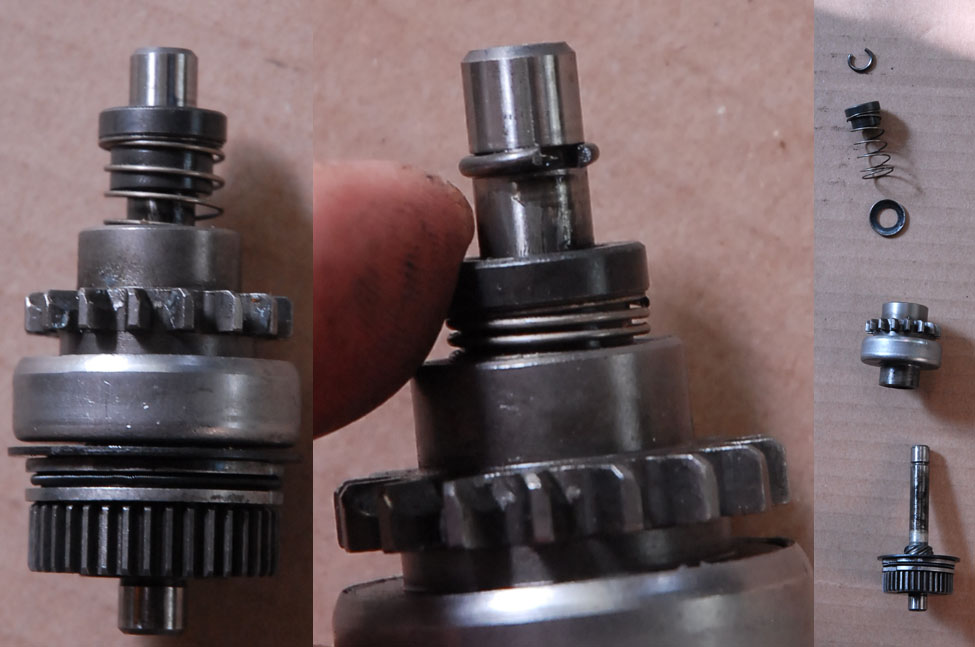

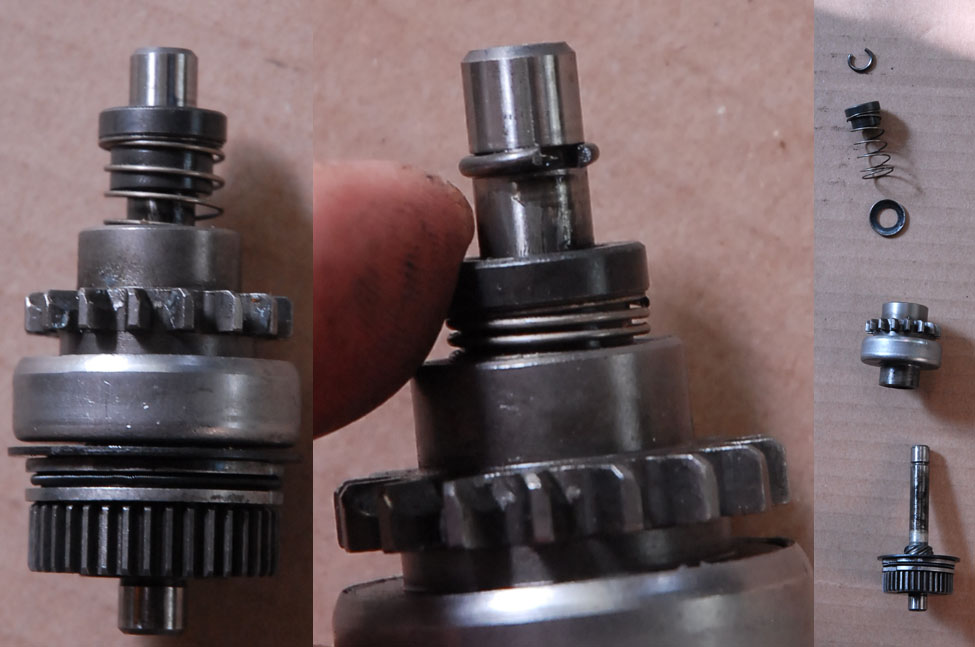

The figure below shows the complete Bendix assembly. The Bendix serves

to automatically engage and disengage the starter from the flywheel

teeth. Grasping the Bendix gear teeth (when assembled to the

starter) and rotating the gear will have two results, depending on

which direction you rotate the gear. In one direction a slip

clutch will simply allow the gear to rotate about the shaft - this is

what happens when the engine starts and the flywheel teeth are moving

faster than the starter motor can turn them. In the other

direction the Bendix gear will move outwards along the shaft, and once

it has reached the end of it's travel, further turning will turn the

shaft and starter motor.

In operation, the motor rapidly reaches full operating speed. The

Bendix assembly has a fair amount of inertia, and it is therefore

easier for it to move outwards along the shaft than it is to suddenly

rotate at the starter speed. This initial 'snap' is what causes

the starter teeth to engage the engine flywheel teeth. Once

engaged, and a load is applied between the gears, the load serves to

keep the Bendix extended. When the engine starts, the load

between the gear teeth reverses, as the flywheel teeth are now moving

faster. This causes the clutch to slip and also to push the

Bendix assembly back towards it's resting position.

Further disassembly will require compressing the spring and

removing the locking ring from the groove on the shaft. Removing

and replacing this ring was the most difficult part of the whole

procedure.

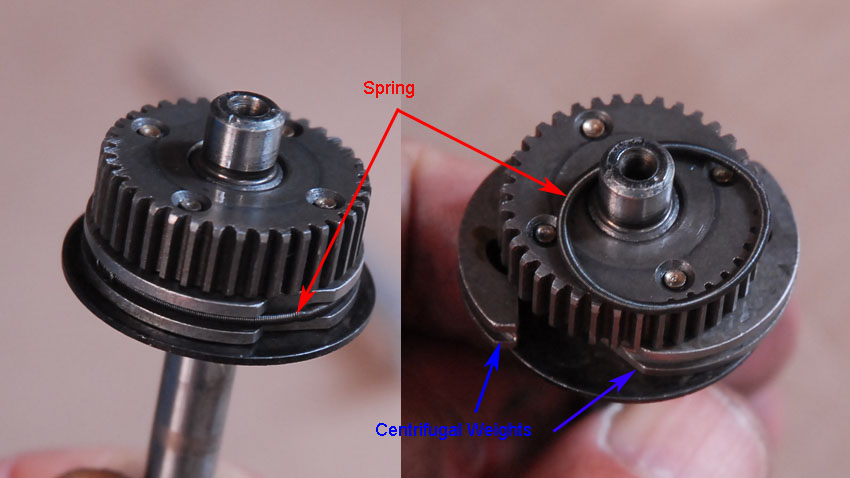

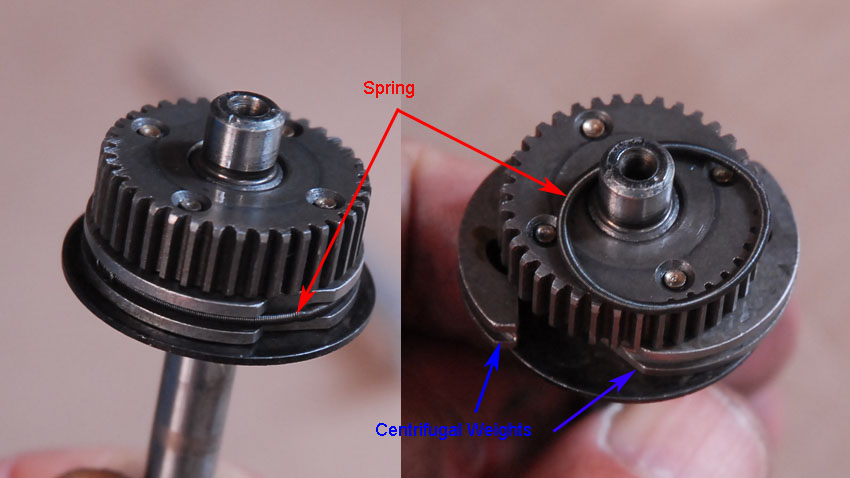

The figure below shows what appear to be

centrifugal weights. A circular spring keeps them compressed

against the shaft, and presumably, at some speed, these weights will

move outward. The left pane shows the assembled unit, the right

pane shows the spring removed and the weights moved to the outer limits

of their travel. I have been unable to figure out the purpose of

these weights, unless it is to provide some friction against the

housing and thereby help to engage the Bendix unit.

(Comment from Peter Mack:

I think the fly weights might act as a brake if the bendix remains engaged after the engine starts, forcing the bendix to disengage. They don't obviously fly out when the motor spins no load, so I'm guessing they only come out on an over-rev situation.